产品介绍产品图纸

本公司生产近30类,计140多种搅拌器,从最常见的(包括已有的HB5标准,SB90标准各种搅拌器)到各种复杂形状或特殊用途的搅拌器。可按H/T2123-91标准的各种规格尺寸系列制造,也可根据用户生产工艺需求,代为设计制造各种特殊要求、特殊规格或特殊用途的搅拌器。

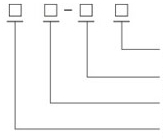

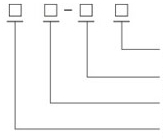

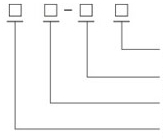

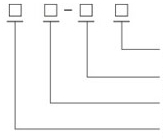

搅拌器型号标注方法:

材料代号

搅拌器轴孔径

搅拌器的外径,

搅拌器型式代号

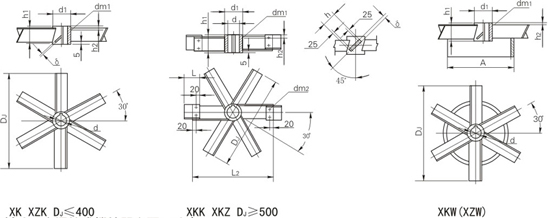

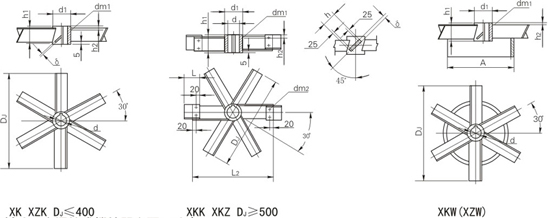

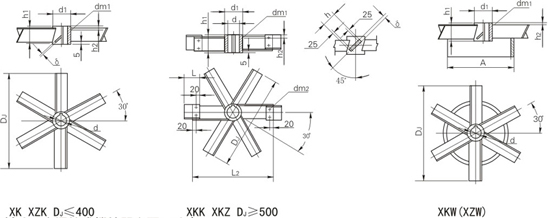

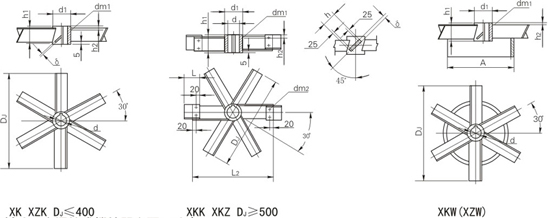

六斜叶开启涡轮式搅拌器

六斜叶整体开启涡轮式XK、六斜叶可拆开启涡轮式XKK、六斜叶稳定环开启涡轮式XKW、六斜窄叶整体开启涡轮式XZK、六斜窄叶可拆开启涡轮式XKZ、六斜窄叶稳定开启涡轮式XZW

本类搅拌器与直叶开启涡轮式比较,除有径向流外有轴向分流,剪切性能介于直叶和弯叶之间,所以它具有较优的综合性能、分散、固体、悬浮、固体溶解都较适合,其它过程也能应用,运作条件同六直叶开启涡轮。

斜叶开启涡轮式搅拌器主要尺寸表

DJ

d

d1

h2

A

L

L2

dm1/dm2

宽形

窄形

δ

宽形重量

窄形重量

h

h1

N/n≤

h

h1

N/n≤

碳钢/不锈钢

150

30

55

12

100

-

-

M12/-

30

55

0.008

20

50

0.0035

6/5

1.1/1.05

0.924/0.914

35

60

1.1/1.05

0.1/0.994

200

30

55

12

140

-

-

M12/-

40

60

0.008

25

55

0.0045

6/5

1.55/1.42

1.233/1.186

40

60

1.57/1.44

1.19/1.142

250

35

55

12

170

-

-

M12/-

50

70

0.011

30

55

0.008

6/5

2.67/2.44

1.438/1.338

40

70

2.68/2.47

1.946/1.868

300

40

70

12

200

-

-

M12/-

60

76

0.018

40

70

0.015

8/5

4.23/3.22

3.12/2.562

45

75

4.26/3.29

3.25/2.689

50

80

4.33/3.37

3.379/2.834

400

45

80

12

270

-

-

M12/-

80

90

0.031

50

80

0.025

8/6

7.3/6.1

5.125/4.506

50

85

7.37/6.18

5.297/4.686

55

90

7.54/6.37

5.469/4.867

500

60

95

16

340

100

380

M16/-M12

100

106

0.089

65

95

0.06

10/8

13.96/11.92

9.301/8.267

65

100

14.1/12.06

9.505/8.481

70

105

14.17/12.17

9.710/8.696

600

65

105

16

400

130

420

M16/-M12

120

120

0.11

75

100

0.08

12/10

23.35/20.34

14.578/13.111

70

110

23.42/20.44

14.825/13.371

80

120

23.66/20.74

15.318/13.888

700

70

115

16

470

180

420

M16/-M12

140

140

0.15

90

110

0.1

12/10

31.75/27.7

20.271/18.193

80

120

32.33/28.3

20.881/18.834

90

135

32.36/28.47

21.492/19.475

800

75

120

18

540

200

480

M16/-M12

160

160

0.23

100

120

0.18

14/12

42.97/39.93

27.91/26.08

85

140

46.53/43.66

30.58/28.87

95

160

49.74/47.00

32.96/31.38

900

80

130

18

600

250

480

M16/-M12

180

180

0.26

115

130

0.21

14/12

55.69/51.25

35.96/33.62

90

150

60.02/55.58

39.08/36.9

100

160

61.20/56.76

39.94/37.8

1000

90

150

18

670

300

480

M16/-M12

200

200

0.29

125

150

0.23

14/12

72.48/67.96

42.52/44.16

100

160

73.79/69.34

48.5/45.86

110

180

79.75/75.6

52.97/50.55

1120

100

160

20

750

360

480

M18/M16

225

225

0.43

140

160

0.34

16/14

99.93/94.65

64.34/61.08

110

180

106.6/101.7

69.11/66.09

120

190

108.6/103.7

70.49/67.54

1250

110

180

20

840

430

480

M18/M16

250

250

0.47

160

180

0.38

16/14

130.2/123.8

84.33/80.54

120

190

132.3/126.1

85.88/82.17

130

200

134.5/128.3

87.44/83.8

1400

120

190

20

940

500

480

M18/M16

280

280

0.53

175

196

0.42

16/14

163/154.8

103.9/98.87

130

200

165.5/157.3

105.5/100.5

140

210

167.9/159.9

107.2/102.3

1600

130

200

25

1070

300

480

M18/M16

320

320

0.77

200

200

0.62

18/16

232.8/222.6

145.5/137.7

140

210

235.5/225.5

147.2/140.9

150

220

238.3/228.4

148.9/142.7

1800

140

210

25

1200

720

480

M18/M16

360

360

0.86

225

210

0.69

18/16

294/283.8

181.5/171.5

150

220

297.1/287

183.3/175

160

240

310.7/301.3

191.2/183.3

2000

150

220

25

1340

820

480

M20/M18

400

400

0.96

250

240

0.77

18/16

363.8/344.4

224.9/214.4

160

240

378.8/360.2

233.9/223.9

170

250

382.7/364.3

236.3/226.4

2240

160

240

30

1500

940

480

M20/M18

450

450

1.32

280

260

1.1

20/18

508.7/489.9

313.7/301.8

170

250

513.1/494.6

316.3/304.5

180

260

517.5/499.3

318.9/307.2

2500

170

250

30

1670

1070

480

M20/M18

500

500

1.47

315

280

1.18

20/18

631.1/607.2

387.7/372.2

180

260

636/612.4

390.5/375.4

190

270

641/617.6

393.2/378.3

备注:搅拌器内孔可根据用户要求制作,轮毂高度一般与内孔相一致。

本公司生产近30类,计140多种搅拌器,从最常见的(包括已有的HB5标准,SB90标准各种搅拌器)到各种复杂形状或特殊用途的搅拌器。可按H/T2123-91标准的各种规格尺寸系列制造,也可根据用户生产工艺需求,代为设计制造各种特殊要求、特殊规格或特殊用途的搅拌器。

搅拌器型号标注方法:

材料代号

搅拌器轴孔径

搅拌器的外径,

搅拌器型式代号

六斜叶开启涡轮式搅拌器

六斜叶整体开启涡轮式XK、六斜叶可拆开启涡轮式XKK、六斜叶稳定环开启涡轮式XKW、六斜窄叶整体开启涡轮式XZK、六斜窄叶可拆开启涡轮式XKZ、六斜窄叶稳定开启涡轮式XZW

本类搅拌器与直叶开启涡轮式比较,除有径向流外有轴向分流,剪切性能介于直叶和弯叶之间,所以它具有较优的综合性能、分散、固体、悬浮、固体溶解都较适合,其它过程也能应用,运作条件同六直叶开启涡轮。

斜叶开启涡轮式搅拌器主要尺寸表

DJ

d

d1

h2

A

L

L2

dm1/dm2

宽形

窄形

δ

宽形重量

窄形重量

h

h1

N/n≤

h

h1

N/n≤

碳钢/不锈钢

150

30

55

12

100

-

-

M12/-

30

55

0.008

20

50

0.0035

6/5

1.1/1.05

0.924/0.914

35

60

1.1/1.05

0.1/0.994

200

30

55

12

140

-

-

M12/-

40

60

0.008

25

55

0.0045

6/5

1.55/1.42

1.233/1.186

40

60

1.57/1.44

1.19/1.142

250

35

55

12

170

-

-

M12/-

50

70

0.011

30

55

0.008

6/5

2.67/2.44

1.438/1.338

40

70

2.68/2.47

1.946/1.868

300

40

70

12

200

-

-

M12/-

60

76

0.018

40

70

0.015

8/5

4.23/3.22

3.12/2.562

45

75

4.26/3.29

3.25/2.689

50

80

4.33/3.37

3.379/2.834

400

45

80

12

270

-

-

M12/-

80

90

0.031

50

80

0.025

8/6

7.3/6.1

5.125/4.506

50

85

7.37/6.18

5.297/4.686

55

90

7.54/6.37

5.469/4.867

500

60

95

16

340

100

380

M16/-M12

100

106

0.089

65

95

0.06

10/8

13.96/11.92

9.301/8.267

65

100

14.1/12.06

9.505/8.481

70

105

14.17/12.17

9.710/8.696

600

65

105

16

400

130

420

M16/-M12

120

120

0.11

75

100

0.08

12/10

23.35/20.34

14.578/13.111

70

110

23.42/20.44

14.825/13.371

80

120

23.66/20.74

15.318/13.888

700

70

115

16

470

180

420

M16/-M12

140

140

0.15

90

110

0.1

12/10

31.75/27.7

20.271/18.193

80

120

32.33/28.3

20.881/18.834

90

135

32.36/28.47

21.492/19.475

800

75

120

18

540

200

480

M16/-M12

160

160

0.23

100

120

0.18

14/12

42.97/39.93

27.91/26.08

85

140

46.53/43.66

30.58/28.87

95

160

49.74/47.00

32.96/31.38

900

80

130

18

600

250

480

M16/-M12

180

180

0.26

115

130

0.21

14/12

55.69/51.25

35.96/33.62

90

150

60.02/55.58

39.08/36.9

100

160

61.20/56.76

39.94/37.8

1000

90

150

18

670

300

480

M16/-M12

200

200

0.29

125

150

0.23

14/12

72.48/67.96

42.52/44.16

100

160

73.79/69.34

48.5/45.86

110

180

79.75/75.6

52.97/50.55

1120

100

160

20

750

360

480

M18/M16

225

225

0.43

140

160

0.34

16/14

99.93/94.65

64.34/61.08

110

180

106.6/101.7

69.11/66.09

120

190

108.6/103.7

70.49/67.54

1250

110

180

20

840

430

480

M18/M16

250

250

0.47

160

180

0.38

16/14

130.2/123.8

84.33/80.54

120

190

132.3/126.1

85.88/82.17

130

200

134.5/128.3

87.44/83.8

1400

120

190

20

940

500

480

M18/M16

280

280

0.53

175

196

0.42

16/14

163/154.8

103.9/98.87

130

200

165.5/157.3

105.5/100.5

140

210

167.9/159.9

107.2/102.3

1600

130

200

25

1070

300

480

M18/M16

320

320

0.77

200

200

0.62

18/16

232.8/222.6

145.5/137.7

140

210

235.5/225.5

147.2/140.9

150

220

238.3/228.4

148.9/142.7

1800

140

210

25

1200

720

480

M18/M16

360

360

0.86

225

210

0.69

18/16

294/283.8

181.5/171.5

150

220

297.1/287

183.3/175

160

240

310.7/301.3

191.2/183.3

2000

150

220

25

1340

820

480

M20/M18

400

400

0.96

250

240

0.77

18/16

363.8/344.4

224.9/214.4

160

240

378.8/360.2

233.9/223.9

170

250

382.7/364.3

236.3/226.4

2240

160

240

30

1500

940

480

M20/M18

450

450

1.32

280

260

1.1

20/18

508.7/489.9

313.7/301.8

170

250

513.1/494.6

316.3/304.5

180

260

517.5/499.3

318.9/307.2

2500

170

250

30

1670

1070

480

M20/M18

500

500

1.47

315

280

1.18

20/18

631.1/607.2

387.7/372.2

180

260

636/612.4

390.5/375.4

190

270

641/617.6

393.2/378.3

备注:搅拌器内孔可根据用户要求制作,轮毂高度一般与内孔相一致。

本公司生产近30类,计140多种搅拌器,从最常见的(包括已有的HB5标准,SB90标准各种搅拌器)到各种复杂形状或特殊用途的搅拌器。可按H/T2123-91标准的各种规格尺寸系列制造,也可根据用户生产工艺需求,代为设计制造各种特殊要求、特殊规格或特殊用途的搅拌器。

搅拌器型号标注方法:

|

|

| 材料代号 | |

| 搅拌器轴孔径 | |

| 搅拌器的外径, | |

| 搅拌器型式代号 |

六斜叶开启涡轮式搅拌器

六斜叶整体开启涡轮式XK、六斜叶可拆开启涡轮式XKK、六斜叶稳定环开启涡轮式XKW、六斜窄叶整体开启涡轮式XZK、六斜窄叶可拆开启涡轮式XKZ、六斜窄叶稳定开启涡轮式XZW

本类搅拌器与直叶开启涡轮式比较,除有径向流外有轴向分流,剪切性能介于直叶和弯叶之间,所以它具有较优的综合性能、分散、固体、悬浮、固体溶解都较适合,其它过程也能应用,运作条件同六直叶开启涡轮。

斜叶开启涡轮式搅拌器主要尺寸表

| DJ | d | d1 | h2 | A | L | L2 | dm1/dm2 | 宽形 | 窄形 | δ | 宽形重量 | 窄形重量 | ||||

| h | h1 | N/n≤ | h | h1 | N/n≤ | 碳钢/不锈钢 | ||||||||||

| 150 | 30 | 55 | 12 | 100 | - | - | M12/- | 30 | 55 | 0.008 | 20 | 50 | 0.0035 | 6/5 | 1.1/1.05 | 0.924/0.914 |

| 35 | 60 | 1.1/1.05 | 0.1/0.994 | |||||||||||||

| 200 | 30 | 55 | 12 | 140 | - | - | M12/- | 40 | 60 | 0.008 | 25 | 55 | 0.0045 | 6/5 | 1.55/1.42 | 1.233/1.186 |

| 40 | 60 | 1.57/1.44 | 1.19/1.142 | |||||||||||||

| 250 | 35 | 55 | 12 | 170 | - | - | M12/- | 50 | 70 | 0.011 | 30 | 55 | 0.008 | 6/5 | 2.67/2.44 | 1.438/1.338 |

| 40 | 70 | 2.68/2.47 | 1.946/1.868 | |||||||||||||

| 300 | 40 | 70 | 12 | 200 | - | - | M12/- | 60 | 76 | 0.018 | 40 | 70 | 0.015 | 8/5 | 4.23/3.22 | 3.12/2.562 |

| 45 | 75 | 4.26/3.29 | 3.25/2.689 | |||||||||||||

| 50 | 80 | 4.33/3.37 | 3.379/2.834 | |||||||||||||

| 400 | 45 | 80 | 12 | 270 | - | - | M12/- | 80 | 90 | 0.031 | 50 | 80 | 0.025 | 8/6 | 7.3/6.1 | 5.125/4.506 |

| 50 | 85 | 7.37/6.18 | 5.297/4.686 | |||||||||||||

| 55 | 90 | 7.54/6.37 | 5.469/4.867 | |||||||||||||

| 500 | 60 | 95 | 16 | 340 | 100 | 380 | M16/-M12 | 100 | 106 | 0.089 | 65 | 95 | 0.06 | 10/8 | 13.96/11.92 | 9.301/8.267 |

| 65 | 100 | 14.1/12.06 | 9.505/8.481 | |||||||||||||

| 70 | 105 | 14.17/12.17 | 9.710/8.696 | |||||||||||||

| 600 | 65 | 105 | 16 | 400 | 130 | 420 | M16/-M12 | 120 | 120 | 0.11 | 75 | 100 | 0.08 | 12/10 | 23.35/20.34 | 14.578/13.111 |

| 70 | 110 | 23.42/20.44 | 14.825/13.371 | |||||||||||||

| 80 | 120 | 23.66/20.74 | 15.318/13.888 | |||||||||||||

| 700 | 70 | 115 | 16 | 470 | 180 | 420 | M16/-M12 | 140 | 140 | 0.15 | 90 | 110 | 0.1 | 12/10 | 31.75/27.7 | 20.271/18.193 |

| 80 | 120 | 32.33/28.3 | 20.881/18.834 | |||||||||||||

| 90 | 135 | 32.36/28.47 | 21.492/19.475 | |||||||||||||

| 800 | 75 | 120 | 18 | 540 | 200 | 480 | M16/-M12 | 160 | 160 | 0.23 | 100 | 120 | 0.18 | 14/12 | 42.97/39.93 | 27.91/26.08 |

| 85 | 140 | 46.53/43.66 | 30.58/28.87 | |||||||||||||

| 95 | 160 | 49.74/47.00 | 32.96/31.38 | |||||||||||||

| 900 | 80 | 130 | 18 | 600 | 250 | 480 | M16/-M12 | 180 | 180 | 0.26 | 115 | 130 | 0.21 | 14/12 | 55.69/51.25 | 35.96/33.62 |

| 90 | 150 | 60.02/55.58 | 39.08/36.9 | |||||||||||||

| 100 | 160 | 61.20/56.76 | 39.94/37.8 | |||||||||||||

| 1000 | 90 | 150 | 18 | 670 | 300 | 480 | M16/-M12 | 200 | 200 | 0.29 | 125 | 150 | 0.23 | 14/12 | 72.48/67.96 | 42.52/44.16 |

| 100 | 160 | 73.79/69.34 | 48.5/45.86 | |||||||||||||

| 110 | 180 | 79.75/75.6 | 52.97/50.55 | |||||||||||||

| 1120 | 100 | 160 | 20 | 750 | 360 | 480 | M18/M16 | 225 | 225 | 0.43 | 140 | 160 | 0.34 | 16/14 | 99.93/94.65 | 64.34/61.08 |

| 110 | 180 | 106.6/101.7 | 69.11/66.09 | |||||||||||||

| 120 | 190 | 108.6/103.7 | 70.49/67.54 | |||||||||||||

| 1250 | 110 | 180 | 20 | 840 | 430 | 480 | M18/M16 | 250 | 250 | 0.47 | 160 | 180 | 0.38 | 16/14 | 130.2/123.8 | 84.33/80.54 |

| 120 | 190 | 132.3/126.1 | 85.88/82.17 | |||||||||||||

| 130 | 200 | 134.5/128.3 | 87.44/83.8 | |||||||||||||

| 1400 | 120 | 190 | 20 | 940 | 500 | 480 | M18/M16 | 280 | 280 | 0.53 | 175 | 196 | 0.42 | 16/14 | 163/154.8 | 103.9/98.87 |

| 130 | 200 | 165.5/157.3 | 105.5/100.5 | |||||||||||||

| 140 | 210 | 167.9/159.9 | 107.2/102.3 | |||||||||||||

| 1600 | 130 | 200 | 25 | 1070 | 300 | 480 | M18/M16 | 320 | 320 | 0.77 | 200 | 200 | 0.62 | 18/16 | 232.8/222.6 | 145.5/137.7 |

| 140 | 210 | 235.5/225.5 | 147.2/140.9 | |||||||||||||

| 150 | 220 | 238.3/228.4 | 148.9/142.7 | |||||||||||||

| 1800 | 140 | 210 | 25 | 1200 | 720 | 480 | M18/M16 | 360 | 360 | 0.86 | 225 | 210 | 0.69 | 18/16 | 294/283.8 | 181.5/171.5 |

| 150 | 220 | 297.1/287 | 183.3/175 | |||||||||||||

| 160 | 240 | 310.7/301.3 | 191.2/183.3 | |||||||||||||

| 2000 | 150 | 220 | 25 | 1340 | 820 | 480 | M20/M18 | 400 | 400 | 0.96 | 250 | 240 | 0.77 | 18/16 | 363.8/344.4 | 224.9/214.4 |

| 160 | 240 | 378.8/360.2 | 233.9/223.9 | |||||||||||||

| 170 | 250 | 382.7/364.3 | 236.3/226.4 | |||||||||||||

| 2240 | 160 | 240 | 30 | 1500 | 940 | 480 | M20/M18 | 450 | 450 | 1.32 | 280 | 260 | 1.1 | 20/18 | 508.7/489.9 | 313.7/301.8 |

| 170 | 250 | 513.1/494.6 | 316.3/304.5 | |||||||||||||

| 180 | 260 | 517.5/499.3 | 318.9/307.2 | |||||||||||||

| 2500 | 170 | 250 | 30 | 1670 | 1070 | 480 | M20/M18 | 500 | 500 | 1.47 | 315 | 280 | 1.18 | 20/18 | 631.1/607.2 | 387.7/372.2 |

| 180 | 260 | 636/612.4 | 390.5/375.4 | |||||||||||||

| 190 | 270 | 641/617.6 | 393.2/378.3 | |||||||||||||

备注:搅拌器内孔可根据用户要求制作,轮毂高度一般与内孔相一致。

-

本公司生产近30类,计140多种搅拌器,从最常见的(包括已有的HB5标准,SB90标准各种搅拌器)到各种复杂形状或特殊用途的搅拌器。可按H/T2123-91标准的各种规格尺寸系列制造,也可根据用户生产工艺需求,代为设计制造各种特殊要求、特殊规格或特殊用途的搅拌器。

搅拌器型号标注方法:

|

|

| 材料代号 | |

| 搅拌器轴孔径 | |

| 搅拌器的外径, | |

| 搅拌器型式代号 |

六斜叶开启涡轮式搅拌器

六斜叶整体开启涡轮式XK、六斜叶可拆开启涡轮式XKK、六斜叶稳定环开启涡轮式XKW、六斜窄叶整体开启涡轮式XZK、六斜窄叶可拆开启涡轮式XKZ、六斜窄叶稳定开启涡轮式XZW

本类搅拌器与直叶开启涡轮式比较,除有径向流外有轴向分流,剪切性能介于直叶和弯叶之间,所以它具有较优的综合性能、分散、固体、悬浮、固体溶解都较适合,其它过程也能应用,运作条件同六直叶开启涡轮。

斜叶开启涡轮式搅拌器主要尺寸表

| DJ | d | d1 | h2 | A | L | L2 | dm1/dm2 | 宽形 | 窄形 | δ | 宽形重量 | 窄形重量 | ||||

| h | h1 | N/n≤ | h | h1 | N/n≤ | 碳钢/不锈钢 | ||||||||||

| 150 | 30 | 55 | 12 | 100 | - | - | M12/- | 30 | 55 | 0.008 | 20 | 50 | 0.0035 | 6/5 | 1.1/1.05 | 0.924/0.914 |

| 35 | 60 | 1.1/1.05 | 0.1/0.994 | |||||||||||||

| 200 | 30 | 55 | 12 | 140 | - | - | M12/- | 40 | 60 | 0.008 | 25 | 55 | 0.0045 | 6/5 | 1.55/1.42 | 1.233/1.186 |

| 40 | 60 | 1.57/1.44 | 1.19/1.142 | |||||||||||||

| 250 | 35 | 55 | 12 | 170 | - | - | M12/- | 50 | 70 | 0.011 | 30 | 55 | 0.008 | 6/5 | 2.67/2.44 | 1.438/1.338 |

| 40 | 70 | 2.68/2.47 | 1.946/1.868 | |||||||||||||

| 300 | 40 | 70 | 12 | 200 | - | - | M12/- | 60 | 76 | 0.018 | 40 | 70 | 0.015 | 8/5 | 4.23/3.22 | 3.12/2.562 |

| 45 | 75 | 4.26/3.29 | 3.25/2.689 | |||||||||||||

| 50 | 80 | 4.33/3.37 | 3.379/2.834 | |||||||||||||

| 400 | 45 | 80 | 12 | 270 | - | - | M12/- | 80 | 90 | 0.031 | 50 | 80 | 0.025 | 8/6 | 7.3/6.1 | 5.125/4.506 |

| 50 | 85 | 7.37/6.18 | 5.297/4.686 | |||||||||||||

| 55 | 90 | 7.54/6.37 | 5.469/4.867 | |||||||||||||

| 500 | 60 | 95 | 16 | 340 | 100 | 380 | M16/-M12 | 100 | 106 | 0.089 | 65 | 95 | 0.06 | 10/8 | 13.96/11.92 | 9.301/8.267 |

| 65 | 100 | 14.1/12.06 | 9.505/8.481 | |||||||||||||

| 70 | 105 | 14.17/12.17 | 9.710/8.696 | |||||||||||||

| 600 | 65 | 105 | 16 | 400 | 130 | 420 | M16/-M12 | 120 | 120 | 0.11 | 75 | 100 | 0.08 | 12/10 | 23.35/20.34 | 14.578/13.111 |

| 70 | 110 | 23.42/20.44 | 14.825/13.371 | |||||||||||||

| 80 | 120 | 23.66/20.74 | 15.318/13.888 | |||||||||||||

| 700 | 70 | 115 | 16 | 470 | 180 | 420 | M16/-M12 | 140 | 140 | 0.15 | 90 | 110 | 0.1 | 12/10 | 31.75/27.7 | 20.271/18.193 |

| 80 | 120 | 32.33/28.3 | 20.881/18.834 | |||||||||||||

| 90 | 135 | 32.36/28.47 | 21.492/19.475 | |||||||||||||

| 800 | 75 | 120 | 18 | 540 | 200 | 480 | M16/-M12 | 160 | 160 | 0.23 | 100 | 120 | 0.18 | 14/12 | 42.97/39.93 | 27.91/26.08 |

| 85 | 140 | 46.53/43.66 | 30.58/28.87 | |||||||||||||

| 95 | 160 | 49.74/47.00 | 32.96/31.38 | |||||||||||||

| 900 | 80 | 130 | 18 | 600 | 250 | 480 | M16/-M12 | 180 | 180 | 0.26 | 115 | 130 | 0.21 | 14/12 | 55.69/51.25 | 35.96/33.62 |

| 90 | 150 | 60.02/55.58 | 39.08/36.9 | |||||||||||||

| 100 | 160 | 61.20/56.76 | 39.94/37.8 | |||||||||||||

| 1000 | 90 | 150 | 18 | 670 | 300 | 480 | M16/-M12 | 200 | 200 | 0.29 | 125 | 150 | 0.23 | 14/12 | 72.48/67.96 | 42.52/44.16 |

| 100 | 160 | 73.79/69.34 | 48.5/45.86 | |||||||||||||

| 110 | 180 | 79.75/75.6 | 52.97/50.55 | |||||||||||||

| 1120 | 100 | 160 | 20 | 750 | 360 | 480 | M18/M16 | 225 | 225 | 0.43 | 140 | 160 | 0.34 | 16/14 | 99.93/94.65 | 64.34/61.08 |

| 110 | 180 | 106.6/101.7 | 69.11/66.09 | |||||||||||||

| 120 | 190 | 108.6/103.7 | 70.49/67.54 | |||||||||||||

| 1250 | 110 | 180 | 20 | 840 | 430 | 480 | M18/M16 | 250 | 250 | 0.47 | 160 | 180 | 0.38 | 16/14 | 130.2/123.8 | 84.33/80.54 |

| 120 | 190 | 132.3/126.1 | 85.88/82.17 | |||||||||||||

| 130 | 200 | 134.5/128.3 | 87.44/83.8 | |||||||||||||

| 1400 | 120 | 190 | 20 | 940 | 500 | 480 | M18/M16 | 280 | 280 | 0.53 | 175 | 196 | 0.42 | 16/14 | 163/154.8 | 103.9/98.87 |

| 130 | 200 | 165.5/157.3 | 105.5/100.5 | |||||||||||||

| 140 | 210 | 167.9/159.9 | 107.2/102.3 | |||||||||||||

| 1600 | 130 | 200 | 25 | 1070 | 300 | 480 | M18/M16 | 320 | 320 | 0.77 | 200 | 200 | 0.62 | 18/16 | 232.8/222.6 | 145.5/137.7 |

| 140 | 210 | 235.5/225.5 | 147.2/140.9 | |||||||||||||

| 150 | 220 | 238.3/228.4 | 148.9/142.7 | |||||||||||||

| 1800 | 140 | 210 | 25 | 1200 | 720 | 480 | M18/M16 | 360 | 360 | 0.86 | 225 | 210 | 0.69 | 18/16 | 294/283.8 | 181.5/171.5 |

| 150 | 220 | 297.1/287 | 183.3/175 | |||||||||||||

| 160 | 240 | 310.7/301.3 | 191.2/183.3 | |||||||||||||

| 2000 | 150 | 220 | 25 | 1340 | 820 | 480 | M20/M18 | 400 | 400 | 0.96 | 250 | 240 | 0.77 | 18/16 | 363.8/344.4 | 224.9/214.4 |

| 160 | 240 | 378.8/360.2 | 233.9/223.9 | |||||||||||||

| 170 | 250 | 382.7/364.3 | 236.3/226.4 | |||||||||||||

| 2240 | 160 | 240 | 30 | 1500 | 940 | 480 | M20/M18 | 450 | 450 | 1.32 | 280 | 260 | 1.1 | 20/18 | 508.7/489.9 | 313.7/301.8 |

| 170 | 250 | 513.1/494.6 | 316.3/304.5 | |||||||||||||

| 180 | 260 | 517.5/499.3 | 318.9/307.2 | |||||||||||||

| 2500 | 170 | 250 | 30 | 1670 | 1070 | 480 | M20/M18 | 500 | 500 | 1.47 | 315 | 280 | 1.18 | 20/18 | 631.1/607.2 | 387.7/372.2 |

| 180 | 260 | 636/612.4 | 390.5/375.4 | |||||||||||||

| 190 | 270 | 641/617.6 | 393.2/378.3 | |||||||||||||

备注:搅拌器内孔可根据用户要求制作,轮毂高度一般与内孔相一致。